Production Process Nonwoven

made of natural fibers

(Flax Nonwoven)

It all starts with the fiber

The fibers, whether flax, hemp or viscose, have to be opened with one or more carding machines. The carded fibrous web is then transported to the entanglement process. Water, which presses against and penetrates the carded fibrous web at high pressure, creates a chemical free, homogeneous, and durable textile fabric. This nonwoven can be embossed or perforated via different structured drums. Finally, the wet nonwoven passes through a drying and inspection process and can already be tailored to customer-specific widths for sale. Depending on requirements, the natural fiber nonwoven can be treated to make it flame-retardant or water-repellent, for example.

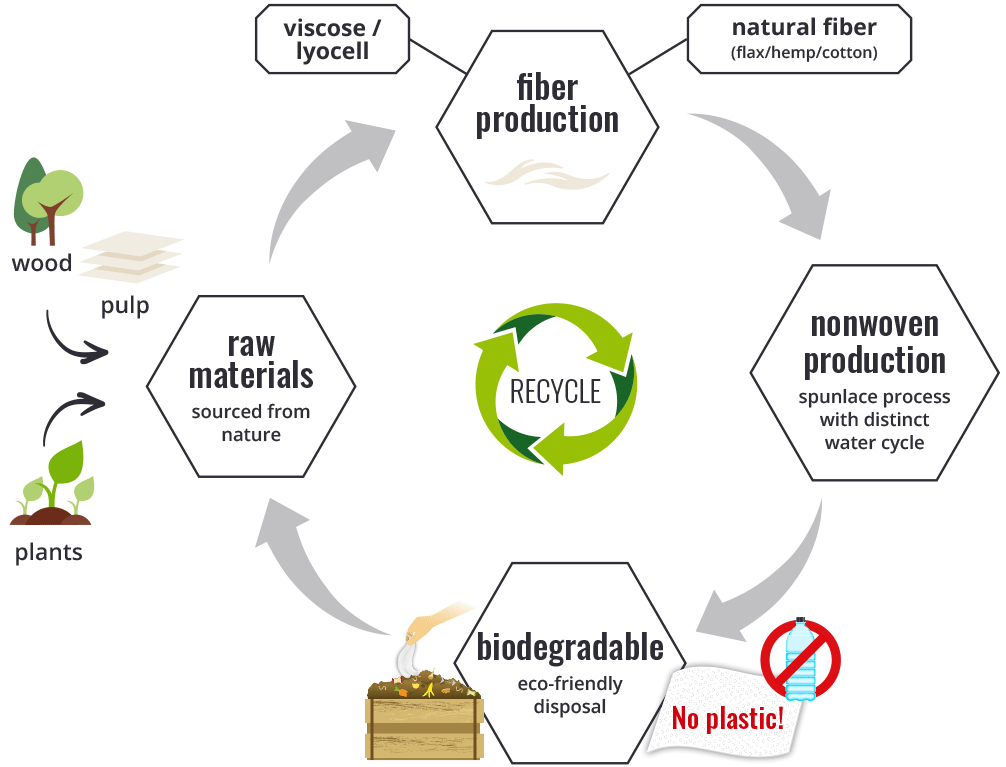

A Natural Cycle

Due to the natural raw materials and gentle production without chemical binders, our natural fiber nonwoven is biodegradable and can be disposed of in an environmentally friendly way.